Professional Padel Court Construction in Houston

Building world-class padel courts with precision engineering and quality craftsmanship

Padel court construction requires specialized expertise, precise engineering, and a thorough understanding of the sport's unique requirements. In Houston's challenging climate—with its intense heat, humidity, and occasional flooding—building a durable, high-performance padel court demands careful planning and quality materials. Our professional construction services deliver courts that not only meet official regulations but also withstand Texas weather conditions while providing an exceptional playing experience.

Whether you're a sports club looking to expand your offerings, a residential property owner seeking a premium recreational amenity, or a developer planning a multi-court facility, proper construction is the foundation of a successful padel court. From site preparation to final installation, every phase must be executed with precision to ensure safety, longevity, and optimal playability.

Service Details

UNDERSTANDING PADEL COURT CONSTRUCTION REQUIREMENTS

Padel courts differ significantly from traditional tennis courts in both dimensions and design. A standard padel court measures 20 meters in length by 10 meters in width, with additional space required for player movement and equipment access. The playing surface sits lower than the surrounding fence line, creating the unique enclosed environment that defines the sport.

The construction process begins with comprehensive site analysis. Houston's clay-heavy soils and propensity for heavy rainfall require careful drainage planning from the very start. Engineers must evaluate ground conditions, determine optimal court orientation to minimize sun glare, and plan for proper water management systems that prevent flooding during Houston's intense storm seasons.

Foundation work is critical to long-term court performance. The base must provide absolute levelness with minimal variation—typically requiring tolerance within 3 millimeters across the entire playing surface. This precision prevents uneven ball bounce, reduces player injury risk, and ensures consistent play characteristics across the entire court. In Houston's expansive soil conditions, proper foundation engineering prevents cracking and shifting that could compromise court integrity.

THE CONSTRUCTION PROCESS: FROM GROUNDBREAKING TO COMPLETION

Professional padel court construction follows a systematic approach that typically spans several weeks. The process begins with site clearing and excavation to the required depth, usually 12 to 18 inches below final grade. This excavation must account for the various layers that will comprise the finished court structure.

Sub-base preparation comes next, involving compaction of native soils and installation of aggregate materials. In Houston's climate, this phase often includes installing French drains and connecting to municipal storm systems to handle the region's heavy rainfall. The sub-base provides structural support while facilitating water movement away from the playing surface.

The base layer installation follows strict specifications for material composition and compaction. Crushed stone or recycled concrete base materials are carefully graded and compacted to create a stable, load-bearing foundation. This layer must achieve specific density requirements through controlled compaction processes, often involving multiple passes with specialized equipment.

Surfacing represents a critical phase where the actual playing characteristics are established. Options include artificial turf systems designed specifically for padel, acrylic hard court surfaces, or specialized cushioned systems. Each surface type offers different play characteristics, maintenance requirements, and durability profiles. Houston's intense UV exposure and temperature variations make surface selection particularly important for long-term performance.

STRUCTURAL COMPONENTS AND MATERIALS

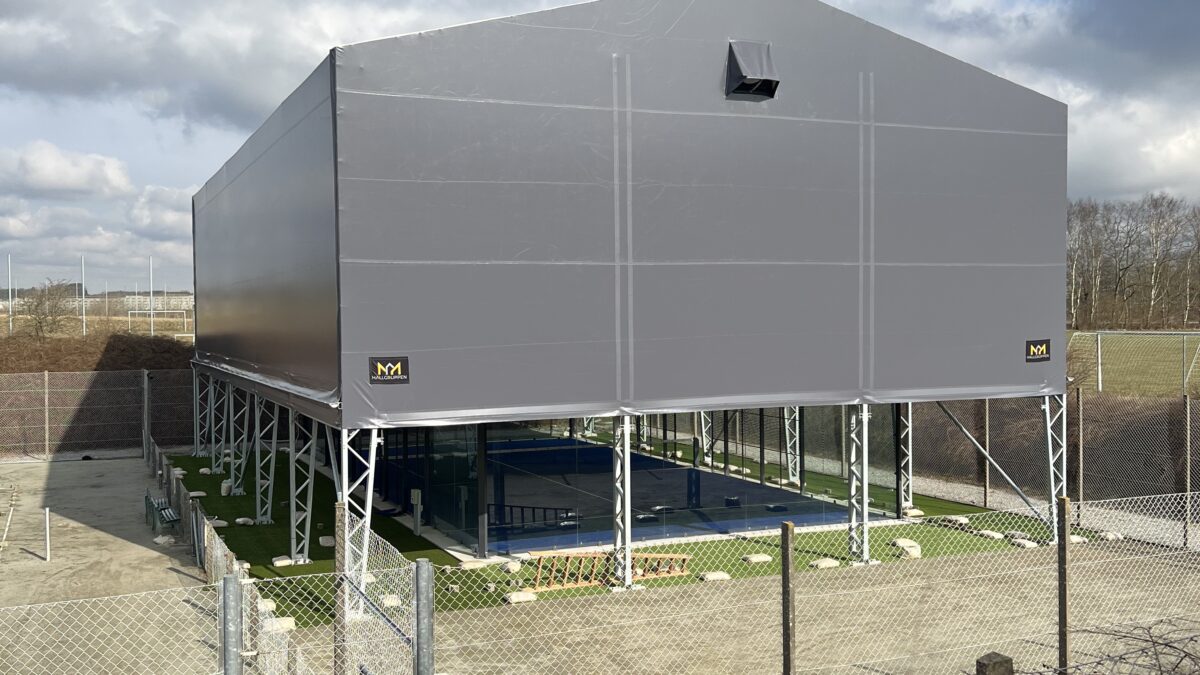

The enclosure system defines padel courts and requires specialized materials and installation techniques. Glass walls—typically 12mm tempered safety glass—form the primary playing surfaces, requiring robust steel frameworks for support. These glass panels must withstand ball impacts, player contact, and environmental stresses while maintaining optical clarity and safety standards.

Metal mesh fencing completes the enclosure, with galvanized and powder-coated steel being the industry standard. Mesh specifications balance visibility requirements with structural strength, typically using 50mm x 50mm grid patterns. All metal components receive protective coatings to resist Houston's humid climate and prevent corrosion over time.

Support structures use heavy-gauge steel posts anchored to concrete foundations extending below the frost line. These foundations must resist lateral forces from wind loads and player impacts while maintaining structural integrity. Connection points between components require careful engineering to prevent stress concentrations that could lead to premature failure.

Lighting systems, when included, require poles rated for wind loads and fixtures designed for sports applications. LED technology has become standard, offering energy efficiency, instant-on capability, and superior light quality for evening play. Electrical infrastructure must meet commercial code requirements and include proper grounding and surge protection.

HOUSTON CLIMATE CONSIDERATIONS IN CONSTRUCTION

Building padel courts in Houston presents unique challenges due to the region's subtropical climate. Summer temperatures regularly exceed 95°F, with heat indexes much higher due to humidity. These conditions affect material selection, construction scheduling, and long-term maintenance requirements.

UV radiation in Texas ranks among the highest in the nation, accelerating degradation of exposed materials. Surface coatings, sealants, and synthetic materials must be specifically rated for high-UV environments. Glass panels receive special treatments to reduce glare and heat transmission, improving player comfort during summer months.

Rainfall and drainage represent ongoing concerns. Houston's flat topography and clay soils create drainage challenges that must be addressed through comprehensive site engineering. French drain systems, catch basins, and connections to municipal storm systems prevent water accumulation that could damage court surfaces or create unsafe playing conditions.

Hurricane preparedness affects structural design requirements. Enclosure systems must withstand high wind loads specified in local building codes. Foundation designs account for potential flooding, with elevated electrical components and water-resistant materials protecting critical infrastructure during storm events.

QUALITY CONTROL AND FINAL INSPECTION

Every construction phase includes quality control checkpoints to ensure compliance with specifications. Foundation work undergoes density testing, concrete work receives slump and strength testing, and surface installations are verified for levelness and consistency.

Final inspection covers multiple aspects: structural integrity of enclosure systems, surface quality and play characteristics, drainage system functionality, and electrical system safety. Documentation includes as-built drawings, material certifications, and warranty information for all major components.

Performance testing verifies that the completed court meets playability standards. Ball bounce tests, surface friction measurements, and enclosure impact tests ensure the facility provides the experience players expect. These tests establish baseline measurements for ongoing maintenance programs.

FREQUENTLY ASKED QUESTIONS

What is included in padel court construction?

Our padel court construction includes site preparation, concrete foundation, steel or aluminum structure, tempered glass walls, artificial turf surfacing, lighting systems (optional), and all necessary accessories. We handle permits and inspections as well.

How long does it take to build a padel court?

A typical padel court construction project takes 4-6 weeks from start to finish, depending on site conditions and weather. This includes site preparation, foundation work, structure installation, surfacing, and final inspections.

Do you handle permits for padel court construction?

Yes, we handle all necessary permits and inspections for padel court construction in Houston and surrounding areas. We are familiar with local building codes and zoning requirements.

GET YOUR FREE QUOTE TODAY

Serving Houston and surrounding areas with professional Padel Court Construction services. Contact us now for a free consultation.